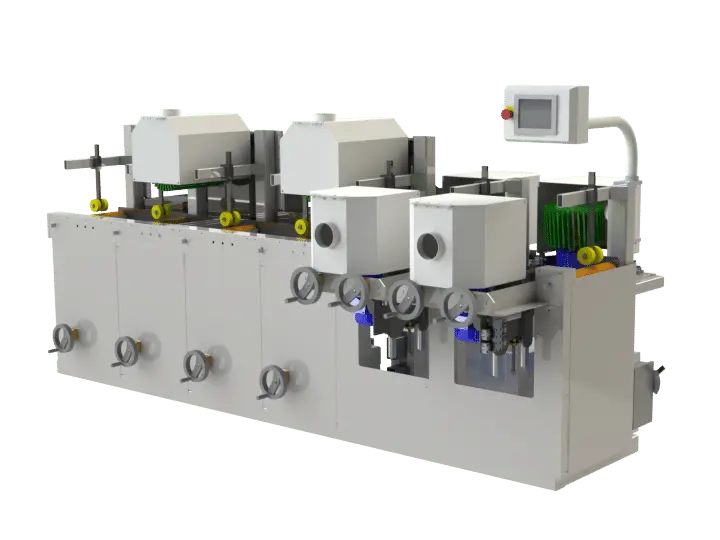

The 5000 Series is designed with a small footprint, is rugged, dependable, and manufactured with as many ‘off the shelf’ parts as possible to minimize downtime and maintenance.

Standard Operation

The top and bottom spindles are belt driven with full power down to 450 RPM. Side heads may be direct drive with horizontal, vertical and tilt adjustments, or belt driven for increased torque. Speed and direction are controlled from the touchscreen. Each motor’s load is also displayed.

Pillar Machine will build the 5000 series machine to fit your needs for width, height, and number of Top, Bottom or Side Heads.

Inverters control the feed rate, spindle speed, and rotational direction. Larger diameter sanding and wire brushes deliver best results. Top and bottom spindles are belt driven for increased torque. Side heads may have tilt and vertical adjustment with direct drive motors, or be belt driven to increase torque.

5000 Advantages:

• fully customizable to suit shop needs

• designed with a small footprint

• ideal for sanding long thick parts

• rugged

• dependable

Machine Specifications:

Operator interface: Manual Control

Standard machine configuration includes: Two top heads

Conveyor width: 15 inch

Material thickness: Up to 6″ thick

Feed Rate: 4 to 47 FPM

Direction of travel through machine: “Right to Left” standard.

Dust Collection Ports: Multiple 4-5″

Dust Collection CFM: 800+

Voltage

208-240 Volt, 3 Phase, 50-60 Hertz

Spindles

Spindle dimensions: 1 1/4″ diameter

Spindle HP: 1 HP (higher HP is available, see option section of this quote for more details)

Spindle RPM: Top head: 200 to 900 RPM

Notes

1. Abrasives not included. Ask your sales rep for recommended abrasives to include with this machine.

Footprint

Length & Weight is dependent on configuration.

We use cookies to improve your experience. Privacy Policy.